Diaphragm-controlled anti-siphon device type HS-V.2

safety device against siphoning according to DWA-A [regulations of the German association for water, wastewater and waste] 779, DWA-A 791, TRÖl [German technical rules for oil installations], DIN 4755 and E DIN EN 12514-3:2009

operating media:

FAME, fuel oil bio, max. 20% (V/V) FAME, fuel oil EL and vegetable oil

- adjustable safety height with ergonomic scaling

- for fuels with different densities

- integrated safety device to prevent overpressure as pressure relief between the anti-siphon device and the burner, for all safety heights

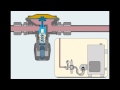

- manual ventilation during start-up

- installation into dome shafts for ambient temperatures of -25 °C to +40 °C

- plastic seal and wire for the subsequent fixture of the safety height

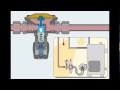

- For the required function check every 5 years, the diaphragm-controlled anti-siphon device is to be equipped with a female thread G 1/8, which is by default equipped with a blind screw but can be retrofitted with a test valve or a test pressure gauge. The version with the test valve enables the direct connection of one of the test pressure gauges to a 5 mm nozzle by means of a hose. The test pressure gauges are subject to test equipment monitoring.

- general type approval no. Z-65.50-492

- construction product for the use in areas prone to flooding and in risk areas

- maximum admissible pressure: PS 10 bar

- flow rate: up to 220 l/h

- safety height: HA = 0.5 to 4.0 m

- connection for blind screw or test valve: G 1/8 F

- The installation of an additional pressure compensation unit as safety device against overpressure (type DAV7, part no. 15 550 00) becomes necessary if the withdrawal fitting at the tank is equipped with a backflow preventer.

Filter

Connection A

Connection B

Packaging

Part no.

Connection A

Connection B

Packaging

Part no.

Article name

Packaging

Part no.