Seamless precision steel pipe

for piping in systems with liquid and gaseous operating media pursuant to EN 10305-1, seamless, cold-drawn

operating media:

diesel, LPG, fuel oil, fuel oil bio, industrial oil, petrol, inflammable gases and liquids of category 1 to 3 and non-flammable gases and liquids as well as water-endangering liquids

The seamless precision steel pipe meets the requirements:

- of AD 2000 instruction sheets HP 100 R and W 4

- of worksheet DWA-A 791

- pursuant to EN 10305-4 / ISO 10763 for connecting compression fittings pursuant to EN ISO 8434-1

- of MVV TB

- technical delivery conditions according to EN 10305-1 and EN 10305-4, steel type E235+N (normal annealed in delivery condition), material number: 1.0308

- dimensions and tolerances according to EN 10305-1 and EN 10305-4

- surface design: galvanised coat according to EN 50961, layer thickness 8 up to 12 μm and with Cr-6-free passivation

- minimum and maximum temperature TS: 0 °C to +300 °C

- If an inspection certificate 3.1 pursuant to EN 10204 is required, please indicate this separately when placing your order.

- The surcharge for wear and tear c0 in the event of corrosion according to AD 2000 instruction sheet B0, also known as the corrosion surcharge c pursuant to EN 13480-3, amounts to c0 = 1 mm for ferritic steels.

It does not apply if the steel is sufficiently protected against the influences of the operating medium. On the other hand, in the event that a heavily corroding operating medium is used, a higher surcharge for wear and tear must be agreed. - The maximum permissible pressure PS (at +20 °C) according to EN 13480-3 is specified in the table of products as case 1 and case 2:

- case 1 (c0= 0 mm) e.g. for LPG

- case 2 (c0= 1 mm) e.g. for fuel oil, water

- The indicated transportation length results from a 5 m rod that is shortened for transportation!

No liability assumed for the specifications for maximum permitted pressure!

For the correct selection and assembly of compression fittings, please refer to the GOK assembly manual and the data sheets for compression fittings and screw-in connectors (at www.gok.de/en/Download-center/Technical-documentation/Data-sheets or www.gok.de/en/Download-center/Technical-documentation/Installation-instructions).

If you are installing a compression fitting with copper or aluminium pipe, you must use a reinforcement ring. For aluminium pipes, use a reinforcement ring made of steel!

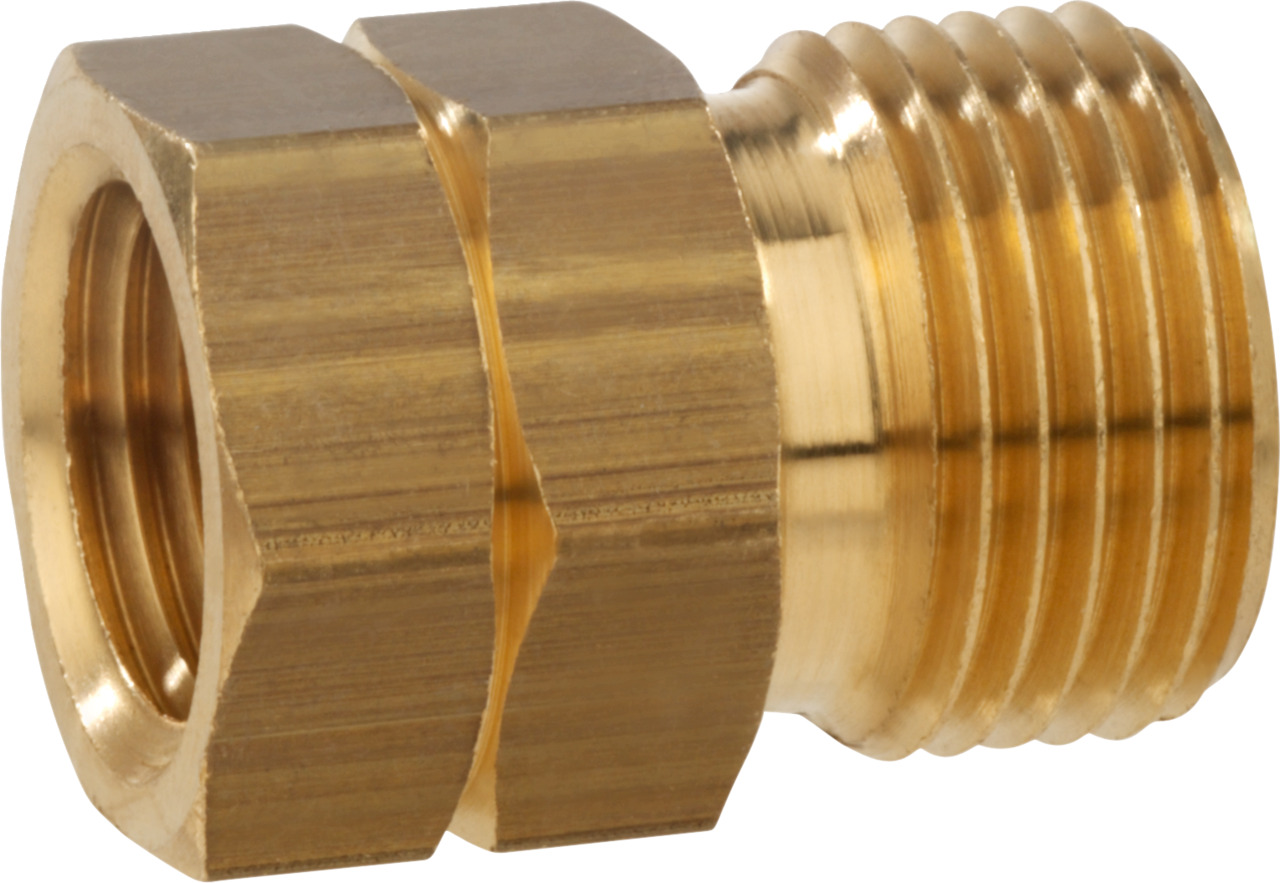

All compression fittings with DVGW type approval certificate according to DIN 3387-1. The DIN 3387-1 standard specifies the requirements and tests for compression fittings (smooth pipe couplings) for connecting metal gas pipes, e.g. within the field of application of TRF (Technical Rules for LPG in Germany). The details of the design of compression fittings are mainly specified in EN ISO 8434-1, DIN 2353 or other standards. For a precise description, the standardised designations according to EN ISO 8434 are used (e.g. EN ISO 8434-1 - SC).

If you are installing a compression fitting with copper or aluminium pipe, you must use a reinforcement ring. For aluminium pipes, use a reinforcement ring made of steel!

All compression fittings with DVGW type approval certificate according to DIN 3387-1. The DIN 3387-1 standard specifies the requirements and tests for compression fittings (smooth pipe couplings) for connecting metal gas pipes, e.g. within the field of application of TRF (Technical Rules for LPG in Germany). The details of the design of compression fittings are mainly specified in EN ISO 8434-1, DIN 2353 or other standards. For a precise description, the standardised designations according to EN ISO 8434 are used (e.g. EN ISO 8434-1 - SC).

Filter

Connection A

Cont.

Maximum admissible pressure

Packaging

Part no.